Smart and advanced greenhouse gutters for the horticultural industry

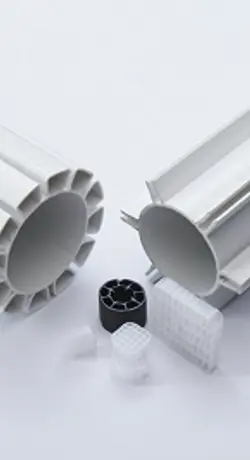

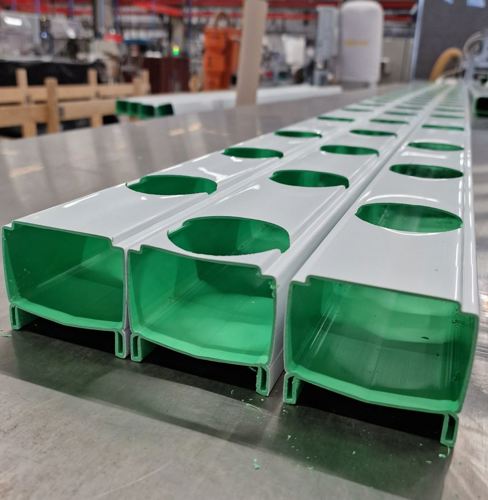

We make your greenhouse gutter profiles with the properties and features you ask for. These include:

- Inline drilling of holes for pots

- End covers or end cups welded by ultrasound

- Bending of drip noses at the end of the line

- RFID tags to capture and send growing data

Customisation makes it easier and quicker for you to get operational. And it gives you the peace of mind that your plants are growing in optimal conditions.

Greenhouse gutters for optimum growth

The living lettuce / head lettuce system

.. is being produced with drilled holes for pots.

The gutters are designed for growing head lettuces and herbs that are sold with their root ball in a pot or as cut head lettuce.

Baby leaf production

.. is grown in open gutters with turf or wool.

Primo’s greenhouse gutters for baby leaf lettuce, herbs and small head lettuces are optimized for growing plants that are sold as cut lettuce.

Saving Water

Our gutters incorporate the Hydroponic Nutrient Film Technique (NFT). The NFT uses irrigation water efficiently and recirculates unused water.

The NFT consumes up to 95% less water compared to conventional field farming.

In addition, as it is a closed system, there is no run-off of fertilizer water into the ground.

Gutters for every application

Redesigned and more sustainable gutters

Our redesigned gutter serves a specific purpose. It makes use of gutters that would otherwise be unusable due to damage or age. These gutters are transformed into a new raw material from which a new gutter can be made.

You can choose the colour of the inner layer of the gutter. On the other hand, the outer layer is deliberately white. This ensures optimum light reflection back into the greenhouse, which benefits plant growth.

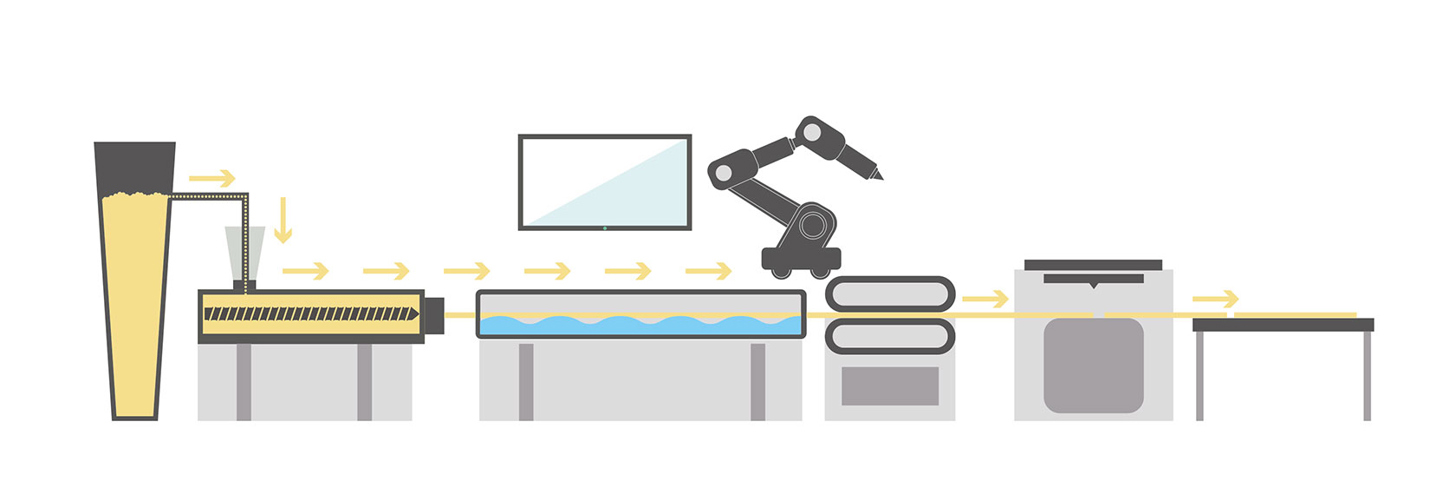

THE EXTRUSION PROCESS

The various types of plastics all have different structures that determine their properties, like rigid or soft, flexible, and so on. These characteristics, and their combinations, are limited only by the imagination.

Reshaping products and igniting innovation in polymer extrusion.

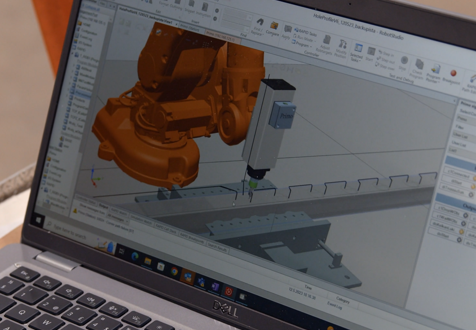

Engaged customers, from designers to engineers, fuel meaningful discussions. Our shared material language combines their needs with our expertise, refining plastic profiles for optimum results.

Decades of cross-industry polymer expertise, makes Primo your dedicated partner providing specialized units for medical tubing, subsea cables, and automotive gaskets..

Clients arrive with finished drawings or sketches, opening doors for collaborative improvement. Thanks to the right polymer, tool, and our material knowledge, we enhance profiles and their functions. With accumulated international experience, we're adept at suggesting superior polymers and faster processes.

The right material is a crucial factor for the properties of your profile and final product. Plastic's adaptability creates intricate shapes, offering flexibility, strength, and diverse applications. Primo leads with superior plastic solutions, embracing sustainability and recyclability.

Versatility: Plastics serve countless roles, from insulation to decoration.

Durability: Resistant to impact, weather, and chemicals, plastics offer reliability.

Efficiency: Low friction suits moving parts, ensuring longevity.

Eco-Friendly: Energy-efficient and recyclable, plastics champion sustainability.

Elevate your products and accelerate time to market with expertise. Our comprehensive approach encompasses tooling, profile design, material expertise, and streamlined development. Harnessing these elements transforms your vision into superior products, while expediting your journey to market success.

For us, every new concept is a new challenge that involves all stakeholders. But our journey doesn't stop there. Every plastic product has the potential for improvement, expansion or material innovation.

Your customers may require additional documentation to meet evolving regulations.

We see the endpoint as an exploration of uncharted territory, a springboard for a new journey ahead.

Computer control and monitoring ensures that all information is updated during production. Our traceability system is an integrated part of our ERP system, Oracle. The quality module that guarantees total control and documentation. All Primo products are fully documented and data sheets can be supplied on request.

Interested in other parts of Greenhouses?

Our Business Areas

Insights

Our people are dedicated to finding solutions to every challenge. That spirit makes for some great stories.

View all news & articles

Do you want to know more about greenhouse gutters?

Janne Mäkisalo

Business Area Manager & Key Account ManagerMeet Janne Mäkisalo, our esteemed expert in gutters and profiles for industrial greenhouses and head of the greenhouse team in the Primo Group, serving a large international customer portfolio, besides his sales responsibilities within the windows & doors industry in Primo Finland's sales team. With many years of experience, Janne is your contact person for customised profile solutions. His deep understanding of industrial greenhouse growing ensures tailor-made profiles that optimise plant growth, energy efficiency and productivity in commercial greenhouses.

Speaks: English, Finnish