PUR: A revolution in the transportation industry

In the transport industry, many producers are looking for alternatives to conventional materials, and the possibilities today are greater than ever before. One such material is PUR – a strong, durable and lightweight composite material ideal for components in commercial vehicles.

In the transport industry, many producers are looking for alternatives to conventional materials, and the possibilities today are greater than ever before. One such material is PUR – a strong, durable and lightweight composite material ideal for components in commercial vehicles.

As demands for sustainability impact the transport industry to an ever increasing degree, producers are turning to new, exciting materials which can enhance durability of every single component in trucks, buses and other types of commercial vehicles. One such material is PUR, which right now is rapidly replacing other, more traditional materials.

Strong, durable and light

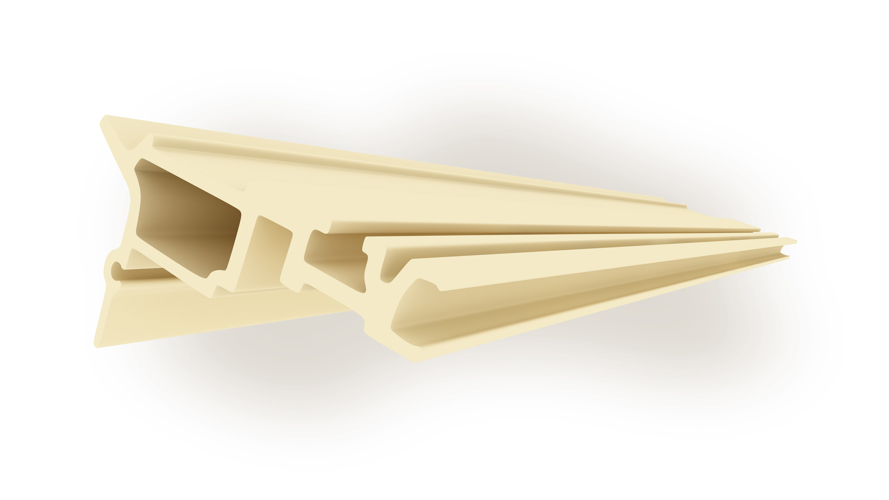

PUR is a composite of glass fibre and a polyurethane polymer. The two materials are mixed and pultruded to form profiles with truly exciting properties and possibilities: Not only is PUR incredibly light, its strength exceeds that of most metals, and it has outstanding thermal properties such as a very high insulation capacity.

PUR profiles can be produced with much thinner walls than comparable profiles made from aluminium or other metals – but with higher tensile strength. Combined with the precision made possible in the pultrusion process, this gives much higher design freedom while saving precious weight. Finally, PUR has very good adhesion properties, making it easy to fit PUR components to a chassis or an exterior surface.

Zero corrosion

As a composite material, PUR cannot corrode and will not deteriorate over time nor lose its attractive appearance. Its strength makes it able to withstand high mechanical forces repeatedly without cracking or loss of load-bearing capacity. This makes PUR ideal for applications where most other materials will wear, crack or degrade, offering makers of transportation equipment the possibility of producing light-weight structural profiles, panels and scuff strips.

Endless possibilities for the transport industry

Managing Director of Primo in Sweden, Jim Nilsson, believes that PUR deserves to be called a real revolution in the transportation industry: “We expect to see rapid growth in the use of PUR profiles in commercial vehicles transportation in the coming years. Not only is this material a true revolution in terms of the possibilities it offers designers and engineers, it’s also highly competitive in both manufacturing and daily use.”

Material experts

Primo has all the expertise and the experience to develop profiles in PUR in collaboration with our customers. Jim Nilsson explains: “We have our own compounding facility, a strong team of material experts and the capability to develop prototypes in a very short time, but most importantly, we have the passion for plastic compounds coupled with many years of experience working with the transport industry. And we’re always ready for the next challenge.”

Countless possibilities for PUR profiles in commercial vehicles

- PUR properties

- Panel assembly profiles

- Panel finishing profiles

- Panel sections

- Sectional door panels

- Panel stiffener profiles

- Scuff strips

- Structural profiles

PUR properties

- Thin walls

- Low weights

- Absence of corrosion

- Thermal insulation

- Thermal break

- Thermal stability

- Good shape stability under impact

- Very good adhesion properties

- Good surface quality and paintability

About Primo

Headquartered in Copenhagen, the Danish group has sales and production activities at 11 locations in Europe and China. The group currently has 980 employees and a turnover of 205 million EUR (per 31.12.2022). The company was founded and owned by the Grunnet family and, since its beginning in 1959, has specialised in designing and producing customer-specific profile solutions in plastic.