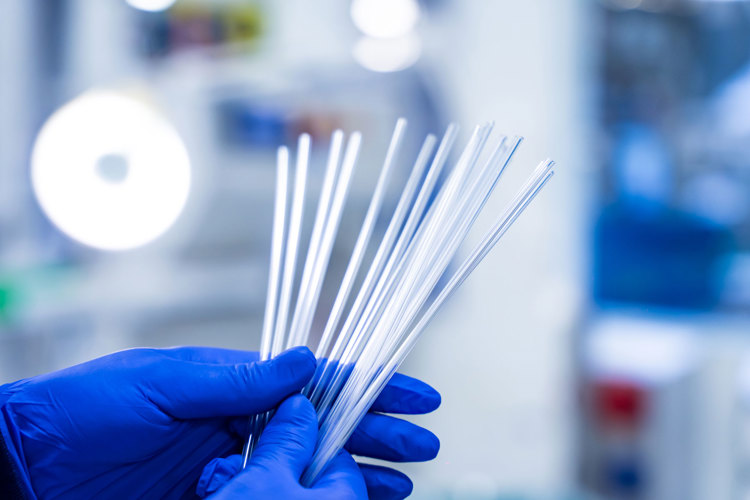

Extruded plastics are the preferred solution for optimum flexibility, hygiene and smooth prototyping in the medical business.

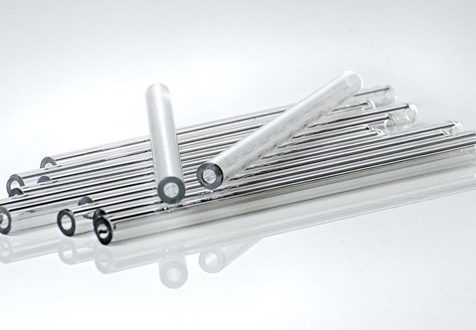

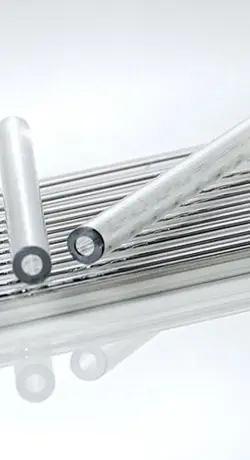

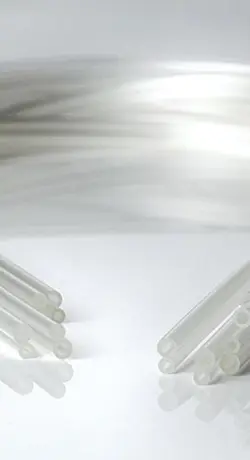

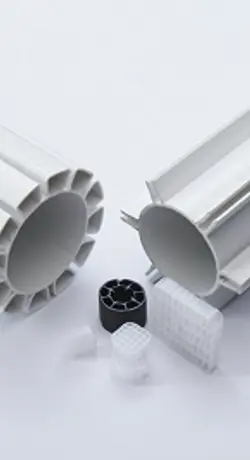

Our plastic medical tubing range comprises:

- Tubing and dispensers for guidewires

- Non-PVC alternative tubing

- Corrugated tubes

- X-ray tubes

- Single and multi-lumen tubes

- Multilayer tubes

- Bubble tubes

- Wire inlay tubing

- Dip-tubes for pharmaceutical, home, and beauty dispensers

- Custom profiles for various medical devices

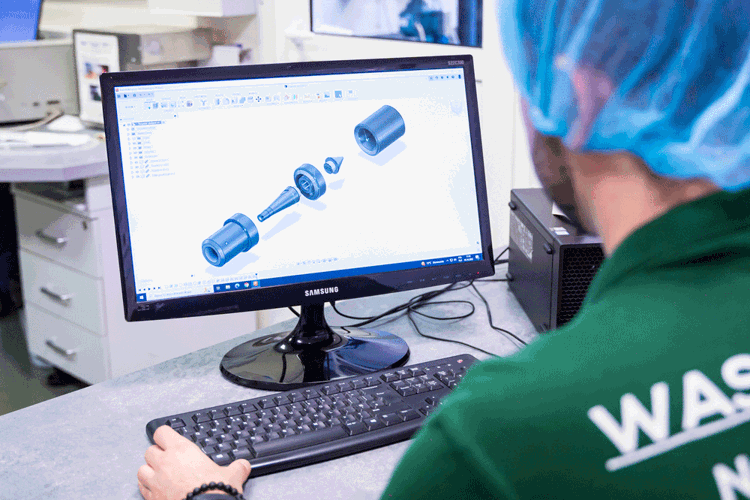

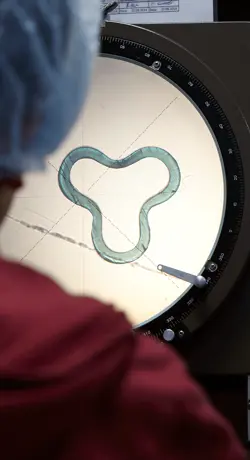

Fast and flexible prototyping

We participate in the product development from start to finish, offering fast and flexible prototyping and on-time delivery, no matter where your production facilities are located.

We offer first-class clean room facilities and a specially trained medical staff, and we take pride in delivering superior quality that meets the high legal requirements of world leading manufacturers in the medical industry. Primo has its own tooling and prototyping center which makes us able to deliver your tubes within just one week.

Do not hesitate to contact us to learn more.