Hans Tranheden

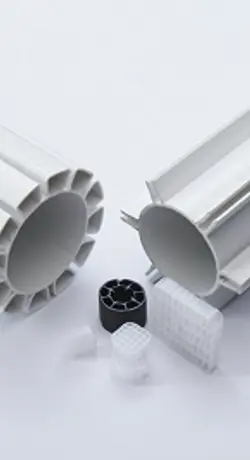

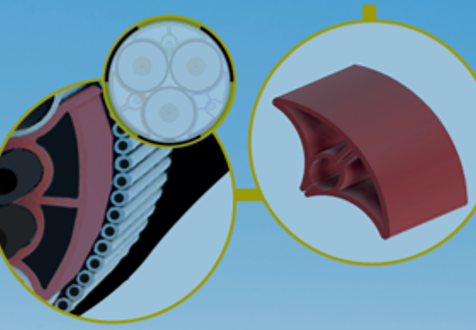

SalesMeet Hans, Primo Sweden’s plastic profile expert for the energy sector and the water treatment industry. We offer tailor-made solutions to industrial batteries, cabling, MBBR & MBR Water filtration profiles, and so much more. As our experienced business area manager in Sweden, you can rely on Hans to find the right plastic profile to your product.

Speaks: English, Swedish