Polymer solutions for building applications

Did you know: Plastics aren’t just plastics. Primo’s extruded profiles are known for their exceptional durability, offering resistance to harsh environmental conditions, chemicals and UV radiation. These unique properties of plastics ensure a longer lifespan and consistent performance in your window, door and sun protecting applications.

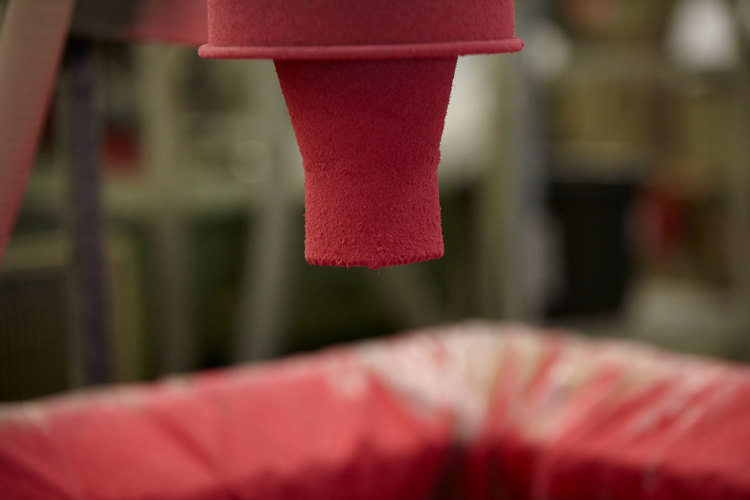

Extruded plastic profiles for the building industry are ideal for windows, doors and sun protection. They can be shaped to almost any requirement to optimise performance in different applications.

In addition, we can select the right plastic materials for any requirement you may have. At Primo, we offer a wide range of high-quality plastic types and blends. We can produce thermoplastics suitable for a wide range of applications e.g. skylights, facades, internal doors, industrial doors, textile screens, awnings etc. From high impact rigid PVC to high performance polymers such as HDPE, PP, ABS and TPE. Our skilled materials specialists are constantly working to develop and improve plastic grades and blends, and even to develop solutions specifically for a particular customer project.

Durable and sustainable

Primo’s extruded profiles are known for their exceptional durability, offering resistance to harsh environmental conditions, chemicals and UV radiation. These unique properties of plastics ensure a longer lifespan and consistent performance in your window, door and sun protecting applications. In addition, thermoplastics are generally recyclable. This means that at the end of their life, PRIMO extruded profiles can be returned to the material cycle.

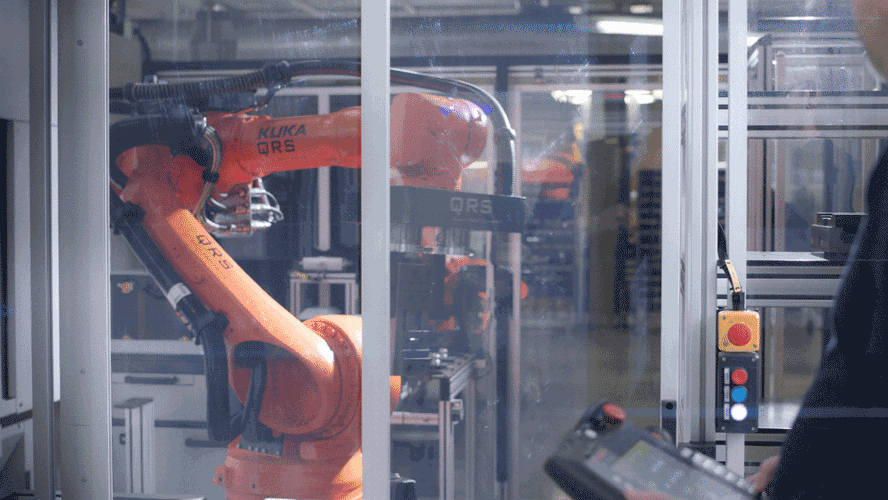

Future-fit technologies

Plastics can be the right choice when it comes to sustainability because they are durable, non-reactive, lightweight and low maintenance.

At Primo, we have set specific sustainability targets for the whole group, with the overall aim of helping our customers to reduce their CO2 emissions. Our FUTURE FIT programme aims to continuously explore new material combinations that include recycled plastics, bio-based plastics, recyclable plastics and/or material types and blends that improve the sustainability profile of the end product in terms of energy efficiency, durability, maintenance, weight and more.

With our sustainable approach, you will not only benefit from high quality extrusion, but we will also help reduce the carbon footprint of your company and your customers.

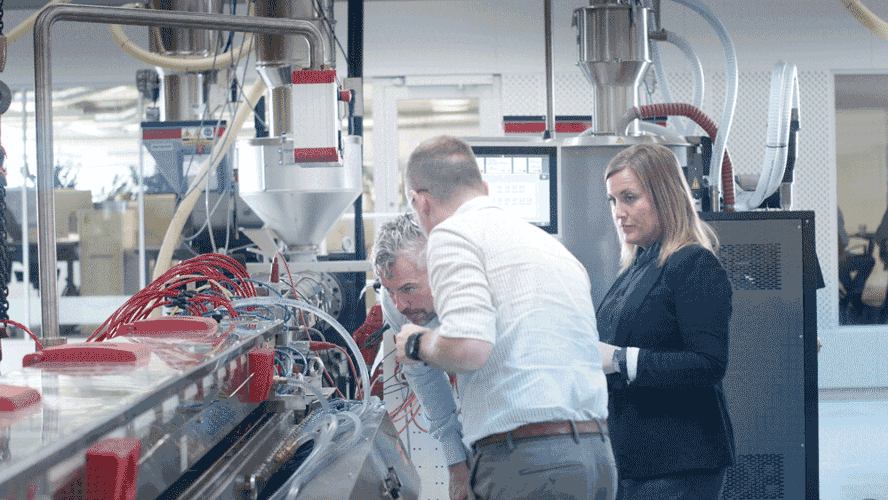

Large scale production capability

Experience our plastic extrusions services, tailored to meet all your specific needs. We guarantee precision engineering including our cutting-edge technology for profiles and sealings for the building industry. This ensures the 24/7 production of custom-designed profiles to exacting dimensions and specifications.

Our commitment to precision allows us to meet unique challenges with a competitive edge in the market.

Experts at Primo Group will support and elevate your projects whereever that may be. Our multi-site approach with 9 production facilities across Europe and China will meet your unique specifications.

Free entry for R+T Stuttgart

Primo will be exhibiting at R+T February 19th to 23rd in Stuttgart. We are located in Hall 10, booth no. 10B95. Learn more and contact us for a free voucher.

About Primo

Headquartered in Copenhagen, Denmark, Primo A/S operates 12 sales and production sites across Europe, China and the USA. Founded in 1959 by the Grunnet family, Primo specializes in custom-designed plastic profile solutions. The company employs around 1000 people and reported a turnover of 180 million EUR as of December 31, 2024.