Linear lenses pave the way for lighting innovation

Linear lenses give designers new possibilities when creating new lighting applications.

The rise of LED as a powerful, low temperature and a small source of light makes it possible to build unique cost efficient and innovative lighting applications.

"We are working with companies who want to challenge the status quo. We are constantly being challenged by customers who want to find new ways of building new lighting products. Here we differentiate ourselves as a plastic extrusion company by going the extra mile to provide the lighting industry with the know-how and manufacturing expertise," says Primo’s Business Area Manager Jaakko Salo.

For instance, Primo's commitment to the lighting industry means that Primo has unique knowledge about extrusion of linear optics.

"We know what is possible. Of course, the customers are experts on optics, but our strength is that we have the material knowledge to make their dreams reality. We can quickly determine what kind of materials will be optimal for certain kinds of applications with regards to physical stress, heat resistance, and diffusion of light,” Jaakko Salo says.

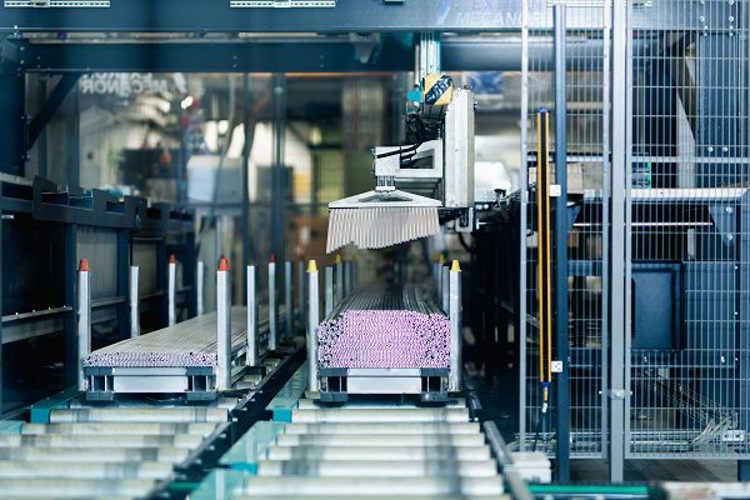

Things are changing quickly in the lighting industry, and Primo is enforcing its presence in the lighting by investing in new production lines. These will be specialised to extrude lighting profiles and offers more freedom for designers. For instance, very precise co-extrusion, meaning extruding multiple materials in the same profile, is expected to be interesting for the industry.

About Primo

Headquartered in Copenhagen, Denmark, Primo A/S operates 12 sales and production sites across Europe, China and the USA. Founded in 1959 by the Grunnet family, Primo specializes in custom-designed plastic profile solutions. The company employs around 1000 people and reported a turnover of 180 million EUR as of December 31, 2024.