Digital stress-testing solves problems before they arise

Stress-testing can also be utilized as an important product documentation. As such, stress-testing is among documentations like fire-resistance and expanded description of chemical composition, offered by Primo as part of our efforts to support customers business when delivering polymer profiles.

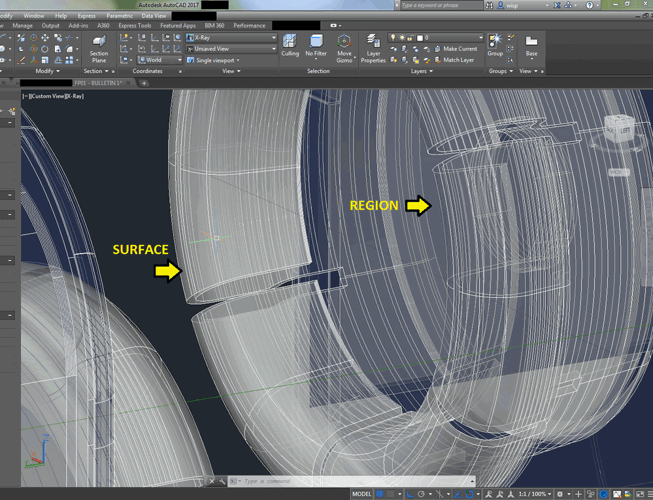

Primo has as a plastic tooling factory for several years been using advanced 2D and 3D software for designing, drawing and stress testing the company’s specialized tools and profiles. Using software such as AutoCAD (2D) and Inventor (3D), the quality of the products is significantly enhanced, and any potential problems can be solved before production is initiated.

Mirko Mirkovic has been one of Primo’s AutoCAD and Inventor experts, since he started working for Primo in 2016, although he has been building his skills with the software for about 20 years.

CAD drawing of extrusion profile

According to Mirko, there are several advantages of using these software packages:

“With AutoCAD and Inventor, we can quickly create drawings, realistic graphics or even film of new profiles and tools. We can also do stress testing on our products.”

Mirko uses the software mainly for window profiles and gaskets, but also for Primo’s specialized profiles and tools.

Overall, using this technology for CAD drawing of extrusion profile is a vital part of Primo’s approach to developing high-quality products, says Mirko:

“We are not only profile producers. We are also a technology center helping our customers by producing simple, high-quality profiles. It is simply a matter of meeting our customers’ high demands.We are not looking for problems, we are solving them”

Especially the stress testing capabilities are important, says Mirko. Stress testing is carried out using a software extension which simulates the physical properties and behavior of the components in various circumstances. This way, the technicians are alerted to potential flaws and can then modify the products accordingly:

“With the stress tests, we as toolmakers can solve any problems before they arise and optimize our designs and tools before the products go into production. This is very important to our customers, because it saves time and money,” says Mirko.

With one important addition:

”My philosophy is: We are not looking for problems, we are solving problems!”

About Primo

Headquartered in Copenhagen, Denmark, Primo A/S operates 12 sales and production sites across Europe, China and the USA. Founded in 1959 by the Grunnet family, Primo specializes in custom-designed plastic profile solutions. The company employs around 1000 people and reported a turnover of 180 million EUR as of December 31, 2024.