Bjørn Hågan

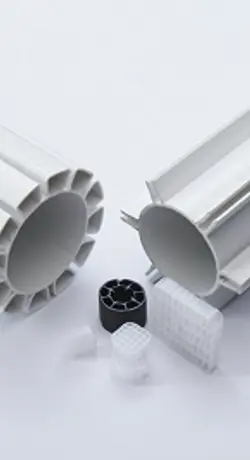

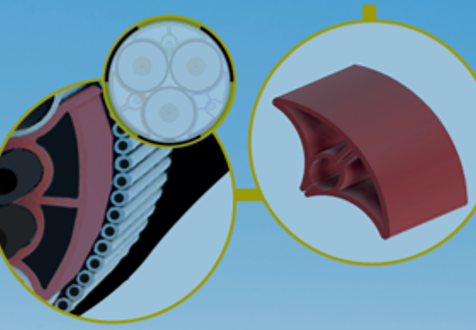

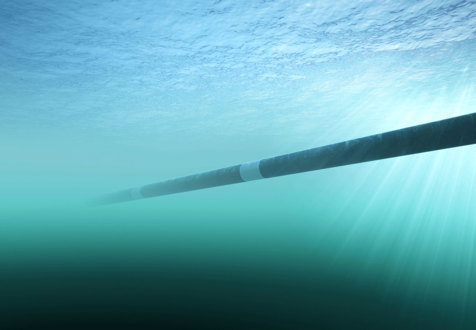

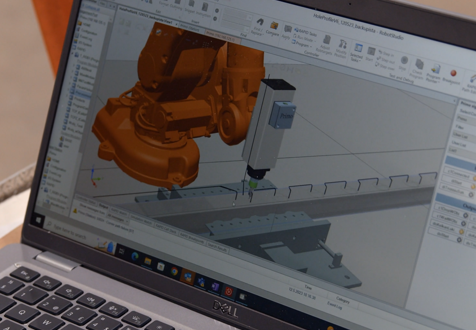

Managing Director at Primo Norge ASAs Managing Director of Primo Norge AS and head of the group's offshore business, Bjørn is at the helm of one of the industry's leading authorities on offshore polymer profiles. With 25 years of professional experience dedicated to Primo, he is a true pioneer in the field. Primo Offshore serves the world's largest suppliers of subsea cabling, an industry that demands state-of-the-art quality and safety. Bjørn is also the contact person for major Norwegian companies in a wide range of industries.

Speaks: English, Norwegian