New composite material can replace aluminium

Strong and sustainable composite superior to aluminium and even steel.

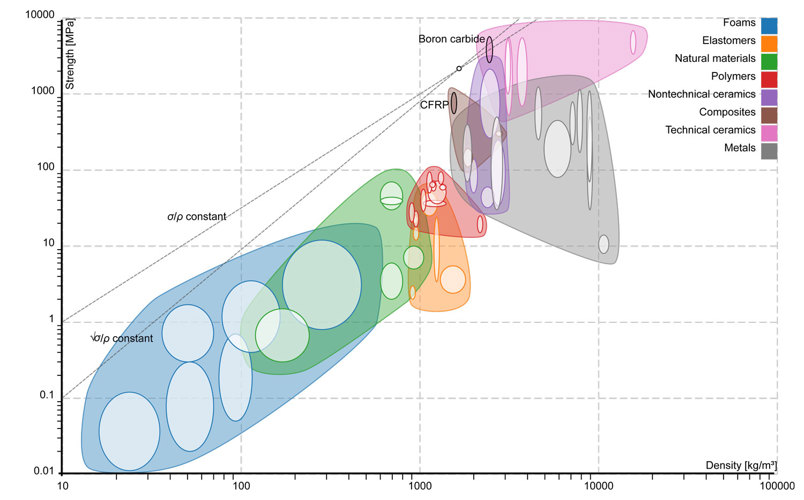

In close cooperation with a client, Primo has developed a new, robust composite material with a low CO2 footprint. Initial tests are promising, with the composite having a high stiffness, high strength-to-weight ratio, high chemical resistance, high temperature tolerance, and low thermal expansion. All these qualities make it a viable alternative to aluminium.

This is good news for a wide range of business areas.

Aluminium has been the go-to product for strength-to-weight ratio for decades. But there is a high energy consumption involved with processing aluminium. This always made it a poor choice from a CO2 perspective.

That changes with the new composite. Initial calculations show a CO2 footprint more than 6 times lower than aluminium. And along with the strength and sustainability benefits, the composite is suitable for inline-processing, such as drilling, stamping and soft gaskets, either extruded together with the profile or mounted for easy disassembly. This makes it an excellent choice for many applications.

Superior to aluminium and even steel

For Tommy Kammersgaard, R&D Manager at Primo Denmark, it's an exciting development.

"We are looking into a future where composites with technical plastics wholly or partly based on recycled elements will be superior to aluminium and even steel in many cases. This will open many exciting business opportunities, for instance, in the window and door, automotive, and many other industries," he says.

Lower environmental impact

It's a view shared with Primo's Group Materials Specialist, Søren Enggaard. He says,

"This is an exciting journey about upcycling materials into a new high-performance engineering polymer that challenges conventional engineering virgin polymers. Not only does the composite have a lower environmental impact, but it also has excellent stiffness and design freedom. Therefore, it can replace aluminium and even steel in many cases, given the right design."

Primo plans to start offering the new composite soon. Key sectors for the new composite include:

- Building

- Business to consumers

- Energy, power and electronics

- Greenhouse

- HVAC and refrigeration

- Medical

- Transportation and traffic

- White goods and climate

- Windows and doors

About Primo

Headquartered in Copenhagen, the Danish group has sales and production activities at 11 locations in Europe and China. The group currently has 980 employees and a turnover of 205 million EUR (per 31.12.2022). The company was founded and owned by the Grunnet family and, since its beginning in 1959, has specialised in designing and producing customer-specific profile solutions in plastic.