Speed is king – Primo’s quest for quality and faster procedures

By understanding and learning from data, internal procedures can be optimised and lead to much faster development processes. This is important to a range of sectors, especially the lighting industry, since it helps companies reaching their markets in time.

Lead-time is becoming an increasingly important parameter: More resources are spent on improving a company’s supply chain across all functions and locations. This includes overseeing the ordering process from the customer orders until they receive it, like production planning, preparation for production, warehousing, shipping and finally invoicing.

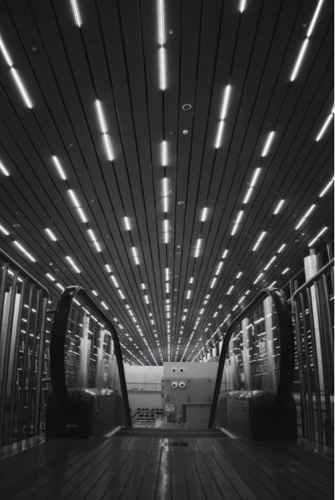

At Primo, we aim at halving the time from idea to product. We believe this is the way. Primo’s project management and in-house tooling are your guarantee for a smooth time-to-market process. This include high flexibility and fast response times whenever refining or alteration work is required. In lighting industry new innovations are constantly developed and with fast and reactive time-to-market process, we can promise that the solutions are truly future fit.

Increased efficiency must not affect quality

At Primo, we gather data from all plants and locations in a streamlined system that monitors the entire production and delivers important insights and reports. We can further optimize our stocks and sourcing processes to secure raw material availability in raw materials such as PC and PMMA, that usually have longer lead times. We are increasing our knowledge about how we produce, and we have established a setup that allows us to learn from each other in the company. Best practices from one plant are now being copied to other productions units. Moreover, we can pinpoint and identify waiting time and take measures to increase effectivity. This way we ensure that our increased efficiency does not affect quality, but only aims at reducing unimportant waiting time.

The advantage of extrusion process and, what Primo offers, is that you can produce different lengths on the same production batch. For the linear LED lighting industry, this allows our clients to easily order profiles for their luminaires with different lengths and benefit from the cost efficiency of mass production.

Fact-based decision making

Studies and experience show that it is crucial to have a transparent setup that allows for decisions based on facts and data. In most cases, this will lead to significant improvements for you and your customers:

- Faster response time

- More precise handling of inquiries

- Smoother processing

- Faster prototyping

- Faster time-to-market

Now, Primo is implementing a new and improved ERP-system. This will make it easier to identify areas of possible improvement. As customer at Primo, the new system will ensure that all decisions and communication are based on hard facts.

About Primo

Headquartered in Copenhagen, the Danish group has sales and production activities at 11 locations in Europe and China. The group currently has 980 employees and a turnover of 205 million EUR (per 31.12.2022). The company was founded and owned by the Grunnet family and, since its beginning in 1959, has specialised in designing and producing customer-specific profile solutions in plastic.